OTBC50 Containerized Ice Block Making Machine

OMT Ice Block Making Machine is a special design for tropical conditions and coastal climate. This machine can be installed into a 40ft or 20ft container, according to ISO, GFRP coated with anti-corrosive treatment. All parts in contact with brine or water are made of stainless steel, galvanized or effectively anti-corrosion treated. Salt water tank is fully insulated and covered by removable panels.

OMT 5ton Containerized Ice Block Making Machine Technical Parameter:

| Model Number | OTB50 |

| Machine Capacity | 5000KG/24HRS |

| Weight of Ice Block | 10KG/PCS (available for 20KG,30KG etc.) |

| Ice Block Size | 100*205*610MM |

| Material | Salt Water Tank | Stainless Steel 304 |

| Ice Molds |

| Ice Freezing Time | 130PCS/6HRS |

| 520PCS/24HRS |

| Refrigerant | R22 |

| Condenser | Water Cooled(Air cooled) |

| Supply Power | 380V, 50Hz, 3P |

| Machine Power | Compressor

Model: HG6/1240-4 | 25HP | 25.7KW |

| Salt Water Pump | 4KW |

| Cooling Water Pump | 2.2KW |

| Cooling Tower Motor | 0.75KW |

| Machinery Unit Dimension | 1870*870*1730MM |

| Salt Water Tank Dimension | 2850*1600*1100MM |

| Warranty | 12 Months |

| Remark | Can be equipped with OCR20 cold room

and crane |

Containerized Ice Block Making Machine Features:

1) Strong and Durable parts.

All compressor and refrigerant parts are world first class.

2) Low energy consumption.

Energy consumption saves up to 30% compare with traditional equipment.

3) Low maintenance, stable performance.

4) High quality material.

The salt water tank and ice moulds are made of stainless steel 304 which is anti-rust and anti-corrosion.

5) Sophisticated heat insulation technology.

The ice making tank adopts high density Polyurethane foam for perfect heat insulation.

OMT 5ton Containerized Ice Block Making Machine Pictures:

| The 40 Feet Container | Machine set and cold room are installed in container |

|  |

| Salt Water Tank(made of stainless steel 304 ) | 30CBM Cold Room(Built of color panels) |

|  |

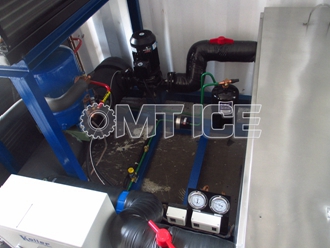

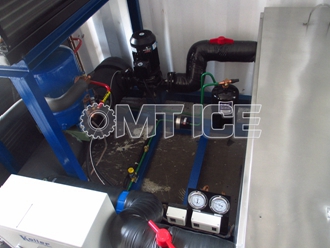

| Germany Bock Semi-Hermetic Compressor | Installation has been Finished |

|  |

OMT Containerized Ice Block Making Machine Series:

| Item | Capacity

(T/24HRS) | Compressor

Power(HP) | Compressor Brand | Refrigerant | Cooling Way | Remark |

| 20 GP Container |

| OTBC10 | 1 | 5(4) | Maneurop/Bitzer/Copeland | R22/R404A | Air Cooled | can be equipped with OCR10

cold room |

| OTBC20 | 2 | 10(9) | Maneurop/Bitzer/Copeland | R22/R404A | Air Cooled | can be equipped with OCR10

cold room |

| OTBC30 | 3 | 14(12) | Bitzer/

Copeland | R22/R404A | Air Cooled | can not be equipped with cold

room |

| 40 GP/HQ Container |

| OTBC30 | 3 | 14(12) | Bitzer/

Copeland | R22/R404A | Water Cooled | can be equipped with OCR20

cold room and crane |

| OTBC40 | 4 | 23(20) | Bitzer/Bock/

Copeland | R22/R404A | Water Cooled | can be equipped with OCR20

cold room and crane |

| OTBC50 | 5 | 28(23) | Bitzer/Bock/

Copeland | R22/R404A | Water Cooled | can be equipped with OCR20

cold room and crane |

| OTBC100 | 6 | 50HP | Bitzer/Bock/

Copeland | R22/R404A | Water Cooled | can be equipped with crane

but not cold room |

⊙ Refrigerant:R22/ R404A

⊙ Supply Power:220V, 60Hz, 3Phase; 380V, 60Hz, 3Phase; 440V, 60Hz, 3Phase;

⊙ Working Conditions: Input Water Temp: 21℃; Ambient Temp: 25℃; Evaporator Temp: -20℃; Condensing Temp: 40℃

⊙ Model and specifications can be changed without notice.

Machine Configuration List:

| Component Item | Brand and Origin |

| Compressor | Manurope/Bitzer/Bock/Copeland |

| PLC controller | Siemens/ Germany |

| Oil separator | EMERSON/ USA |

| Electrical components | LG (LS)/South Korea |

| Solenoid valve | CASTAL/Italy |

| High pressure controller | DANFOSS/ Denmark |

| Low pressure controller | DANFOSS/ Denmark |

| Expansion valve | CASTAL/Italy |

| Condenser | Jianguo/Xuemei |

| Evaporator | OMEX/Guangzhou |

OTB50 Ice Block Machine-for 1000pcs of 5kg Ice

OTB50 Ice Block Machine-for 1000pcs of 5kg Ice  OMT 1000kg Tube Ice Machine

OMT 1000kg Tube Ice Machine  OTCS300 Small Capacity Ice Cube Machine

OTCS300 Small Capacity Ice Cube Machine  OMT 2000kg Tube Ice Machine

OMT 2000kg Tube Ice Machine  OTC20 Cube Ice Machine

OTC20 Cube Ice Machine  OTCS500 Commercial Ice Cube Machine

OTCS500 Commercial Ice Cube Machine