OMT 10ton industrial tube ice machine

OMT 10ton industrial tube ice machine is a large capacity 10,000kg/24hrs.For this machine,all water and ice contact area of tube ice machine are made from Stainless Steel 304 Grade. It provides corrosion resistance to tubes and makes cleaning of tubes ice machine very easy.

OMT 10ton Industrial Tube Ice Machine Technical Parameter:

| Model Number | OT100 |

| Machine Capacity | 10,000kg/24 hours |

| Tube Ice Outer Diameter | 28mm,34mm |

| Tuce Ice Length | 27mm~50mm |

| Material of Mainframe | Stainless Steel 304 |

| Compressor Brand | Bock(Bitzer/Copeland) |

| Refrigerant | R22 |

| Cooling Way | Water Cooled(Air cooled) |

| Supply Power | 220V~480V, 50Hz/60Hz, 3P |

Machine

Power | Compressor(HP) | 50 | 43.58KW |

| Ice Cutter Moter(KW) | 1.1 |

| Circulating Water Pump(KW) | 1.5 |

| Cooling Water Pump(KW) | 2.2 |

| Cooling Tower Motor(KW) | 1.5 |

| Machinery Unit Size (mm) | 2200*1900*2550 |

| Machine Unit Weight(kg) | 3200 |

| Coolig Tower Weight(T) | 50 |

| Warranty | 12 months |

OMT Industrial Tube Ice Machine Features:

1) Strong and Durable parts.

All compressor and refrigerant parts are world first class.

2) Compact structure design.

Shot installation period and greatly save installation space.

3) Low-power consumption and minimal maintenance.

4) High quality material.

The machine mainframe is made of stainless steel 304 which is anti-rust and anti-corrosion.

5)PLC program Logic Controller.

Provides multiple functions such as automatically turn on and shut down. Ice falling and Ice outgoing automatically, can be connect with automatic ice packing machine or convery belt.

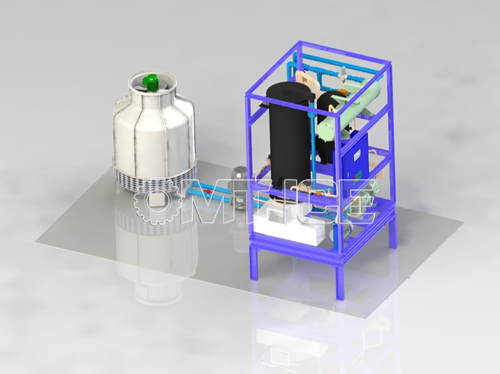

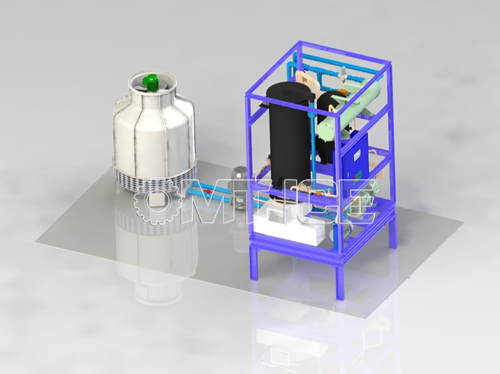

OMT 10ton Industrial Tube Ice Machine Pictures :

| Machine Front View | Cooling Tower |

|  |

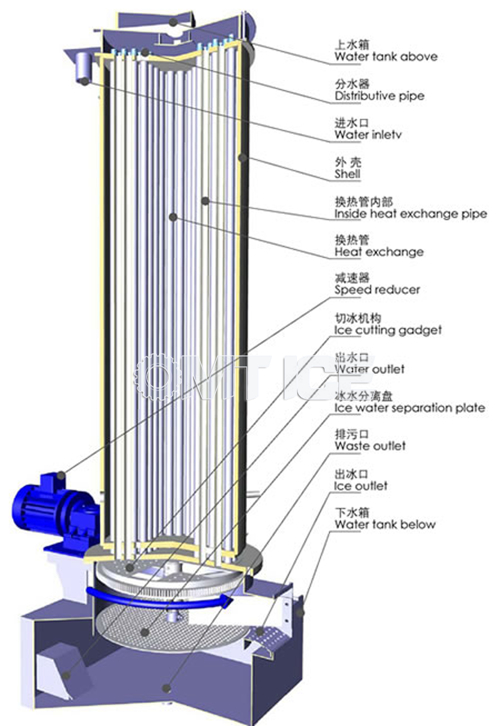

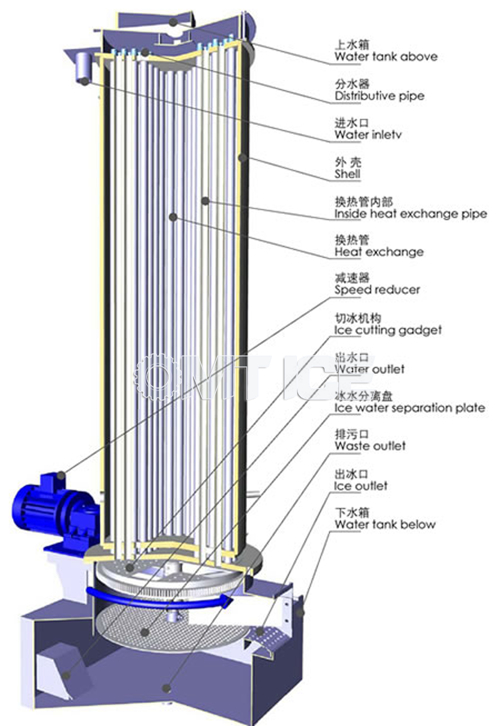

| Tube Ice Machine Schematic Diagram | Evaporateor Schematic Diagram |

|  |

| OMT Tube Ice Far View | OMT Tube Ice Close View |

|  |

OMT Tube Ice Machine Series:

| Item | Capacity

(Ton/day) | Compressor Power(HP) | Ice Cutter

Power(KW) | Circulating Water Pump (KW) | Cooling Water

Pump(KW) | Cooling Tower

Pump (KW) | Cooling Fan

Motor(KW) | Machine Unit

Size(MM) |

| OT10 | 1 | 4 | 0.37 | 0.37 | / | / | 0.36 | 1600*1350*2010 |

| OT20 | 2 | 12 | 0.37 | 0.75 | / | / | 0.9 | 1550*910*2010 |

| OT30 | 3 | 15 | 0.55 | 1.1 | 1.5 | 0.37 | / | 1680*950*2200 |

| OT50 | 5 | 20 | 0.75 | 1.1 | 2.2 | 0.75 | / | 1750*1020*2250 |

| OT80 | 8 | 40 | 1.1 | 1.5 | 2.2 | 1.5 | / | 2200*1900*2400 |

| OT100 | 10 | 50 | 1.1 | 1.5 | 2.2 | 1.5 | / | 2200*1900*2550 |

| OT120 | 12 | 2*25 | 1.1 | 1.5 | 2.2 | 1.5 | / | 2300*2130*2100 |

| OT150 | 15 | 2*40 | 2.2 | 2.2 | 4 | 1.5 | / | 2650*2130*2100 |

| OT200 | 20 | 2*50 | 2.2 | 2.2 | 5.5 | 1.5 | / | 2800*2130*2100 |

⊙ Tube ice outer diameter:Φ28mm and Φ34mm;

⊙ Supply Power: 380~420V, 50Hz, 3Phase; 220V, 60Hz, 3Phase; 380V, 60Hz, 3Phase; 440V, 60Hz, 3Phase;

⊙ Standard Working Conditions: Input water temp: 21℃; Ambient temp: 25℃; Condensing temp: 40℃;

⊙ Model and specifications can be changed without notice.

Machine Configuration List:

| Component Item | Brand and Origin |

| Compressor | Bock/Bitzer/Copeland |

| PLC controller | Siemens/ Germany |

| Oil separator | EMERSON/ USA |

| Electrical components | LG (LS)/South Korea |

| Solenoid valve | CASTAL/Italy |

| High pressure controller | DANFASS/ Denmark |

| Low pressure controller | DANFASS/ Denmark |

| Expansion valve | CASTAL/Italy |

| Condenser | Jianguo/Xuemei |

| Evaporator | OMEX/Guangzhou |

OTB50 Ice Block Machine-for 1000pcs of 5kg Ice

OTB50 Ice Block Machine-for 1000pcs of 5kg Ice  OMT 1000kg Tube Ice Machine

OMT 1000kg Tube Ice Machine  OTCS300 Small Capacity Ice Cube Machine

OTCS300 Small Capacity Ice Cube Machine  OMT 2000kg Tube Ice Machine

OMT 2000kg Tube Ice Machine  OTC20 Cube Ice Machine

OTC20 Cube Ice Machine  OTCS500 Commercial Ice Cube Machine

OTCS500 Commercial Ice Cube Machine